Tube Plugs

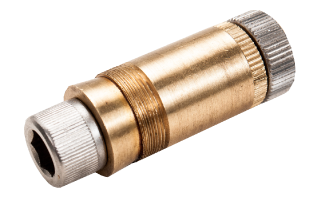

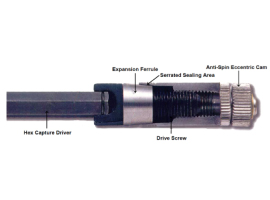

Elliott’s Torq N’ Seal Mechanical Tube Plugs create a positive mechanical contact seal in excess of 6,500 PSI (448.2 bar), making them ideal for high-pressure applications.

-

Tube Size: 0.410” to 1.000 (10.4 to 25.4mm) ID

-

Maximum Pressure: 6,500 PSI

-

Materials: Brass, Steel, Stainless, Titanium, and more.

-

ASME PCC-2-2015 Compliant

-

Comprehensive Testing and Quality Assurance Standards.

-

Easy To Install- No Hydraulic Equipment Needed.

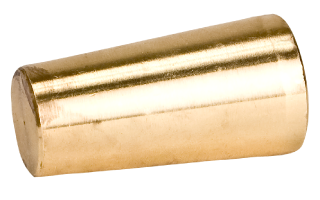

Elliott’s One-Piece Tube Plugs cover a wide tube OD range, making them ideal for sealing leaky tubes in both heat exchangers and boilers.

-

Tube Size: 0.375" to 3.000" (9.5 - 76.2mm) OD

-

Maximum Pressure: 150 PSI

-

Materials: Brass, Carbon Steel, Stainless Steel, Aluminum, Monel, and more.

Elliott’s Two-Piece Tube Plugs offer more sealing due to the tapered pin design. This gives even expansion to the ring and a long contact to the seal.

-

Tube Size: 0.375” to 1.250 (9.5 - 31.8mm) OD

-

Maximum Pressure: 150 PSI

-

Materials: Brass, Carbon Steel, Stainless Steel, Aluminum, and more.

Suggested Articles

The Evolution Of The Tube Plug

There have been many variations of the tube plug over the years in an effort to achieve maximum sealing area and to control the method in which it is installed. While each of these plugs are still commonly used today, they were designed to overcome various challenges operators have had over the years.

Selecting The Correct Tube Plug Material

Selecting The Correct Tube Plug Material Not having a compatible tube plug material can result in leaks, costing hundreds of thousands of dollars or more in lost production and revenue. When plugging a “leaker” (leaking [...]

How To Select The Right Tube Plug

When it comes to selecting a tube plug, there are a variety of options and factors to consider: application, material, and the ID of the tube. The three main types of tube plugs offered are one-piece, two-piece, and mechanical.

MB Engineering Services Found Effective And Simple Way To Plug Heat Exchanger Tubes

MB Engineering Services Found Effective And Simple Way To Plug Heat Exchanger Tubes Download The Results Report Quick Summary The Challenge MB Engineering Services must selct the right tools [...]

Why Vent Tubes?

One of the most overlooked best practices for plugging a tube is to vent the tube beforehand. Tube venting is a process by which a small puncture is made inside of the tube, releasing any pressure or chemicals that may be trapped inside.

How To Remove An ETT Mechanical Tube Plug

While mechanical tube plugs are strong enough to remain inside of tubes for long periods of time, in cases where they are going to be removed it is important to follow these three tips and tricks.