Tube Installation

As the original tube tool company, Elliott invented and perfected the tube expander. Elliott manufactures tube expanders for many applications including condensers, chillers, heat exchangers, firetube and watertube boilers, and sugar vacuum pans.

-

Tube Size: 0.250" to 4.000" (6.4 -101.6mm) OD

Elliott has a full line of tube rolling equipment to suit your application needs. Elliott has both electric and pneumatic tube rolling motors that work powerfully to expand tubes in the most demanding applications.

-

Tube Size: 0.250" to 6.000" (6.4 - 152mm) OD

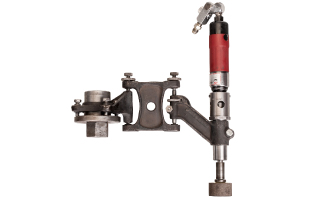

Elliott offers 4 different assisted tube rolling systems: Table Hawk, Rapid Hawk Electric, Rapid Hawk Hybrid, and the Monster Hawk. Each system comes equipped with a variety of features to suit a specific industry application.

-

Tube Size: 0.25" to 3.00" (6.35 - 76.2mm) OD

Elliott’s Tube Hole Gauges make it easy to accurately measure tube IDs and tube sheet holes found in vessels such as heat exchangers, chillers, and surface condensers.

-

Tube Size: 0.375” to 2.000” (9.5 – 51.0mm) OD

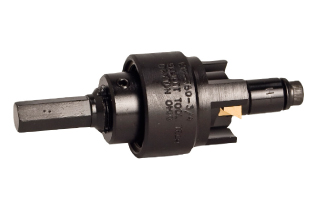

Elliott’s GT Series Grooving Tools, also known as Serrating Tools, can be used manually to clean up existing grooves or can be used in milling or drilling equipment for OEM tube sheet thicknesses of 3/8” (9.5mm) through 2-1/8” (54.0mm).

-

Tube Size: 0.375" to 3.000" (9.5 - 76.2mm) OD

Elliott’s ETF Series Tube End Facers are ideal for trimming heat exchanger, condenser, and chiller tubes to a specific tube projection after tube expansion.

-

Tube Size: 0.375" to 1.500" (9.5 - 38.1mm) OD

Elliott’s Tube Pilots, also known as Tube Guides, are used to pilot replacement tubes through tube sheets and tube support plates that are commonly found in heat exchangers and surface condensers.

-

Tube Size: 0.500” to 1.500” (12.7 – 38.1mm) OD

Elliott’s ELC110220 is the first torque control with an Embedded Logic Controller that senses and is compatible with both 110V or 220V automatic, and manual reverse rolling motors.

-

Tube Size: 0.250" to 3.000" (6.4 - 76.2mm) OD

-

Voltage: 110V to 240V

-

Languages: English or Spanish

-

Compatibility: Elliott’s 99 Series Electric Rolling Motors (other electric motors with optional adapters)

-

Auto-Reverse

Elliott’s Tube Sheet Hole Brushes clean and remove hard deposits from tube sheets and support plate holes in surface condensers and heat exchangers.

-

Tube Size: 0.250” to 1.250” (6.4 – 31.8mm) OD

Elliott’s Hand Hole Seat Grinder is air-powered, light, easy to handle, and precision-engineered to reface boiler header seats.

-

Seat Width: 0.187" to 0.656" (4.8 - 16.7mm)

Elliott's Pneumatic Hammer is the recommended tool for removing tube stubs in heat exchangers or beading tubes in firetube boilers.

-

Tube Size: 0.250" to 3.000" (6.4 - 50.8mm) OD

Elliott’s Lubricants are engineered to provide the best lubrication in tube rolling and roll beading applications. They will provide time and tool savings compared to commonly available lubricants.

-

Paste Lubricant

-

Liquid Lubricant

-

Bead Coolant

-

Cutting Oil

Suggested Articles

Elliott Announces A Faster Way To Expand Small Heat Exchanger Tubes

Elliott Announces A Faster Way To Expand Small Heat Exchanger Tubes New and improved design expands tubes faster than any Elliott expander before, now at a lower price. DAYTON, OH [...]

Choosing The Right Rolling Motor

With a wide variety of rolling motors on the market, choosing the right one can seem overwhelming. There are several factors to consider when selecting a rolling motor. Power source, torque control, RPM, [...]

Rolling Motors & Torque Control

There are two motor power sources that are used for expanding tubes mechanically: electric rolling motors and pneumatic rolling motors. Determining what motor to use for a job will depend on operator preference, availability of electricity or air, and the application.

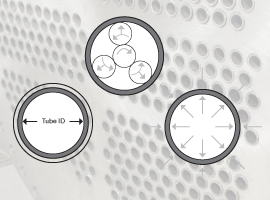

How to calculate roll ID

Tube Expanding is based on engineering principles, involving elasticity and plasticity, to compress the OD of the tube against a fixed container, such as rolling tubes into tube sheets, drums, ferrules or flanges. To assure a proper tube joint, the tube wall must be reduced by a predetermined percentage. The following chart can be used for determining the correct tube wall reduction.

Expanding Fire Tube Boiler Tubes

Basic Principles Of Tube Expanding Expanding Fire Tube Boilers Firetube boiler tubes consist of an expanded and beaded tube end. The method for achieving a bead has advanced [...]

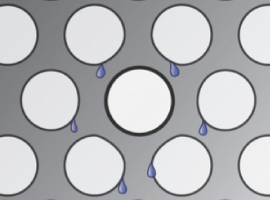

Materials, Tube Leaks, & Pre-Expansion Steps

Basic Principles Of Tube Expansion Materials, Tube Leaks, & Pre-Expansion Steps Tubing Material Below are materials and percentages that can be used as a guideline when rolling tubes [...]