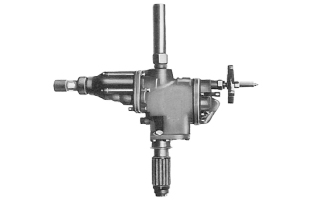

Tube Rolling Motors

ET850 Series

Torque Controlled Pneumatic Rolling Motor

Elliott's ET850 Motor is the next evolution of push-pull motors. Offering the same USA quality and performance you're used to, with additional features to improve the operator's experience.

-

Tube Size: 0.750” to 1.250” (19.1 – 31.8mm) OD

-

Type: Rolling Motor

-

Power: Pneumatic

-

Torque: Torque Controlled

ET720 Series

Torque Controlled Pneumatic Rolling Motor

The ET Motors are ideal for rolling small tubes commonly found in oil coolers and other small heat exchangers. These motors have undergone extensive testing, proving long tool life and quality.

-

Tube Size: 0.250” to 0.375” (6.35 – 9.525mm) OD

-

Type: Rolling Motor

-

Power: Pneumatic

-

Torque: Torque Controlled

Elliott’s Stall Torque Pneumatic Rolling Motors are the most powerful motors available for rolling tubes in extreme applications. The motors are recommended for use in heavy wall, thick drum applications in watertube boilers.

-

Tube Size: 0.750” to 6.000” (19.1 – 152.4mm) OD

-

Type: Rolling Motor

-

Power: Pneumatic

-

Torque: Stall Torque

99 Series

Electric Rolling Motors

Elliott’s 99 Series electric rolling motors offer better consistency, faster RPMs, and comparable torque to that of pneumatic offerings.

-

Tube Size: 0.250” to 3.000” (6.4 – 76.2mm) OD

-

Type: Rolling Motor

-

Power: Electric 110V or 220V

-

Torque: Torque Controlled with ELC

445 Series

Right Angle Pneumatic Rolling Motors

The powerful 445 Series Motors are ideal for tough boiler tube applications. The right angle heads are suitable for rolling tubes in hard to reach, tight areas. Now available in torque controlled & stall type motors.

-

Tube Size: 2.000” to 4.000” (50.8 – 101.6mm) OD

-

Type: Right Angle Pneumatic Rolling Motor

-

Style: Torque Controlled or Stall Type

Midi/Maxi Series

Torque Controlled Pneumatic Rolling Motor

The Midi/Maxi Series Pneumatic Rolling Motors are manufactured with quality materials to provide motor robustness and durability for years to come.

-

Tube Size: 0.750” to 2.000” (19.1 – 50.8mm) OD

-

Type: Rolling Motor

-

Power: Pneumatic

-

Torque: Torque Controlled

Suggested Articles

Elliott Announces A Faster Way To Expand Small Heat Exchanger Tubes

Elliott Announces A Faster Way To Expand Small Heat Exchanger Tubes New and improved design expands tubes faster than any Elliott expander before, now at a lower price. DAYTON, OH [...]

Choosing The Right Rolling Motor

With a wide variety of rolling motors on the market, choosing the right one can seem overwhelming. There are several factors to consider when selecting a rolling motor. Power source, torque control, RPM, [...]

Rolling Motors & Torque Control

There are two motor power sources that are used for expanding tubes mechanically: electric rolling motors and pneumatic rolling motors. Determining what motor to use for a job will depend on operator preference, availability of electricity or air, and the application.

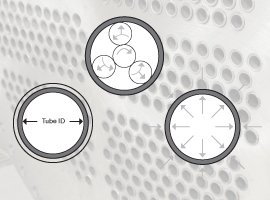

How to calculate roll ID

Tube Expanding is based on engineering principles, involving elasticity and plasticity, to compress the OD of the tube against a fixed container, such as rolling tubes into tube sheets, drums, ferrules or flanges. To assure a proper tube joint, the tube wall must be reduced by a predetermined percentage. The following chart can be used for determining the correct tube wall reduction.

Expanding Fire Tube Boiler Tubes

Basic Principles Of Tube Expanding Expanding Fire Tube Boilers Firetube boiler tubes consist of an expanded and beaded tube end. The method for achieving a bead has advanced [...]

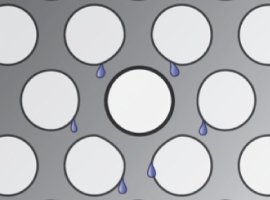

Materials, Tube Leaks, & Pre-Expansion Steps

Basic Principles Of Tube Expansion Materials, Tube Leaks, & Pre-Expansion Steps Tubing Material Below are materials and percentages that can be used as a guideline when rolling tubes [...]