Rolling Motors & Torque Control

Types Of Rolling Motors

There are two motor power sources that are used for expanding tubes mechanically: electric rolling motors and pneumatic rolling motors. Determining what motor to use for a job will depend on operator preference, availability of electricity or air, and the application.

Electricity offers better consistency when rolling tubes and is more readily available than air. Electric is the best option when you’re trying to roll to a very specific ID, because there’s less variation. Pneumatic motors offer faster speeds and more power; however, they can be susceptible to fluctuations in air supply. Pneumatic would be preferred in larger boiler applications because of the higher torque required to move a large amount of material.

Electric Rolling Motor

Pneumatic Rolling Motor

Types Of Torque Control

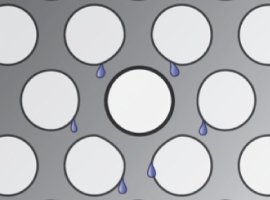

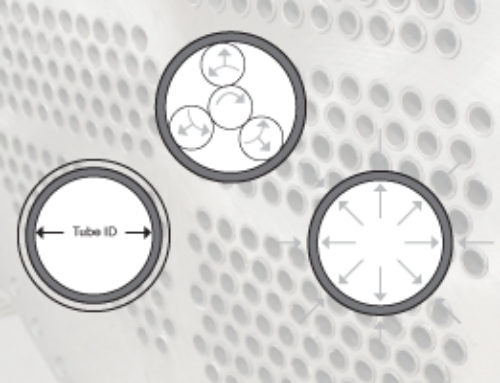

Torque controlled tube expanding is the most popular method for tube expansion because it compensates for variables which the operator/technician cannot control, such as sheet hole ID variance and tube wall thickness tolerances.

Electronic Digital Torque Control

Electronic Torque Control

When using an electrical energy source for tube expansion, an Electronic Digital Torque Control monitors the power required by the electric rolling motor to properly expand the tube. This is done by constantly monitoring the amperage (amp) draw of the tube expansion motor.

As the rolling motor provides rotation during the rolling operation, the added resistance of reducing the tube wall requires additional electrical power. As this wall crush resistance increases, the motor’s amperage usage increases. Adjustable selections on the torque control allow the operator to establish a cut-off point which, when reached, will stop the electrical power to the motor. An LED readout on the control indicates the actual amperage usage of the rolling motor during all phases of the operation. Since this process references motor power requirements after metal-to-metal contact (tube to sheet hole), any variances in tube or sheet hole dimensions are diminished.

Pneumatic Torque Control

Pneumatic Torque Controlled Rolling motors are similar in practice to electronic tube expansion motors. As resistance is encountered during the wall reduction of tube expansion, the pneumatic torque control shifts a valve that stops the flow of compressed air to the motor. Power is reapplied as the motor is activated in reverse to release the tool from the tube.

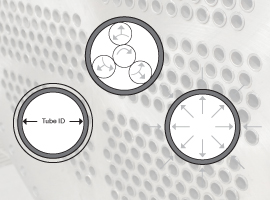

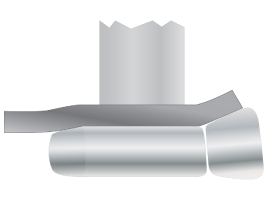

Dimensional Rolling

Dimensional rolling is when an operator rolls a tube to a predetermined size, by stopping the forward travel of the mandrel. This can be done with either visual cues or by setting a mandrel stop. This restriction limits the diameter the rolls will expand, allowing for consistent and repetitive size control. For dimensional rolling to be accurate and repeatable, the tubes must have very controlled wall thicknesses and diameters, and the tube sheet hole diameters must be held to close tolerances. This is process is usually used in roll beading applications and the generation bank of a water tube boiler.