Chemical Plant’s Fabrication Shop Reports 10X More Life Than EGI Spears

Quick Summary

The Challenge

- Turn around vessels quickly with high customer satisfaction.

- Poor performance and inconsistent quality from EGI spears was hindering production.

The Solution

- Trial Elliott’s E-Series hex spears to compare quality and performance.

The Results

- Tool life was 10x better with Elliott.

- Reduced downtime due to spear breakage.

- Improved productivity.

The Challenge

A chemical plant and international leader in the production of nylon, plastics and synthetic fibers has a large fabrication shop located in southern U.S.A that provides maintenance and creation of new vessels.

The shop manager is challenged with eliminating wasted labor and increasing production. Working on as many as three vessels at once, the fabrication shop must manage its time and resources well to maintain quick turnaround and customer satisfaction. Part of their maintenance work includes tube removal. The preferred method of removal is to manually pull tubes with spears. The fabrication shop was previously using EGI spears because of their lower price but had noticed poor tool performance and inconsistencies in tool life.

The EGI spears would often break down on the pulling teeth or snap in two pieces, sometimes after only pulling one or two tubes.

The Solution

The fabrication shop chose to test Elliott E-Series hex spears because they can withstand 2,500 more ft/lb of force exerted upon them than the EGI spears. Their engineered design lowers the chance that the gripping end of the spear will break off in the tube, saving time, money and hassle.

In order to determine if this tooling choice would be the right fit, the shop manager tested Elliott E-Series hex spears versus EGI spears side by side on 1.250” 11 BWG stainless steel tubes.

The Results

The fabrication shop significantly reduced their tooling costs and labor by using Elliott’s E-Series hex spears.

Elliott’s E-Series hex spear tool life was much greater during the testing, pulling more than 10 times the amount of the EGI spears and consistently pulling over 50 tubes each. The Elliott hex spears provide the tool life needed by the fabrication shop, with no downtime since their engineered design lowers the chance of the spear breaking off in the tube, eliminating wasted labor and increasing their production.

The EGI spears consistently pulled less than 5 tubes. Every time an EGI spear broke inside the tube, operators needed to spend 15-20 minutes to remove the spear and start the process again, greatly decreasing efficiency. “We pulled 10 times as many tubes with Elliott’s spears, eliminating wasted labor and increasing our production,” noted the shop manager.

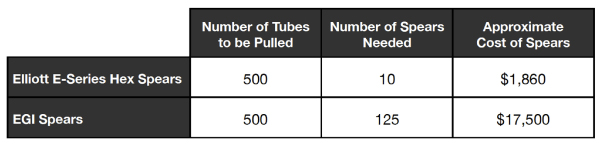

Considering a similar job with 500 tubes, using Elliott E-Series hex spears would eliminate 25 hours in downtime due to spear breakage and save over $15,000 in tooling cost.