The Superior Method For Joining Tubing To Flanges And Fittings.

Easily create secure, leak-proof joints between ductile tubular products and fittings with the Elliott Mechanical Joining Tool.

Superior Joints

Roll To A Torque Or Diameter Spec

Easy To Use

Materials

See It In Action!

Superior joints

Creates secure, leak-proof joints between ductile tubular products and fittings. Mechanically joined joints will not leak, pull apart, or come loose due to pressure, vibrations or temperature change. Superior to a welded, brazed, or crimped joint.

Roll To A Torque Or Diameter Spec

Rolling to a torque ensures consistent results regardless of tolerance and variations of the tube OD, wall thickness, and component ID. Rolling to a diameter guarantees a consistent ID of the tube. This makes it possible to “iron out” and round up the ID of the tube.

Easy To Use

Limited training required to operate. Used on manual electric rolling motors, pneumatic motors, special machines and in rare cases, on CNC machines.

Operating Procedure

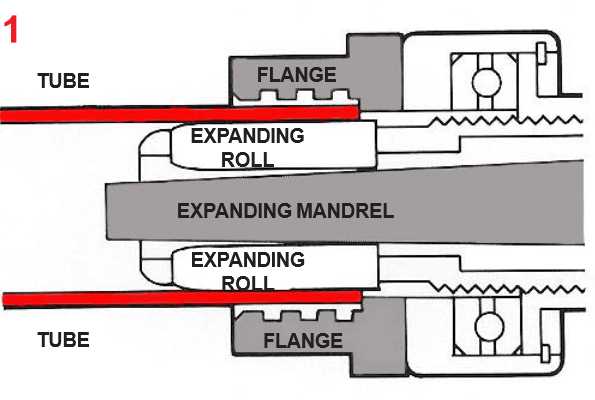

1) 0% Expansion

The tube is inserted into the flange and the mechanical joining tool is inserted into the tube.

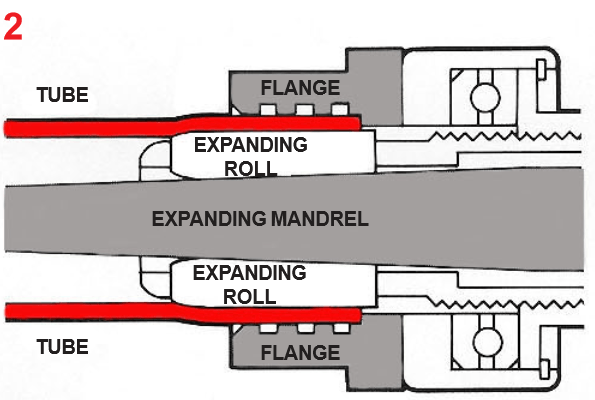

2) 25% Expansion

When the tube has been rolled to roughly 25% of the total expansion required, the tube will make metal-to-metal contact with the flange.

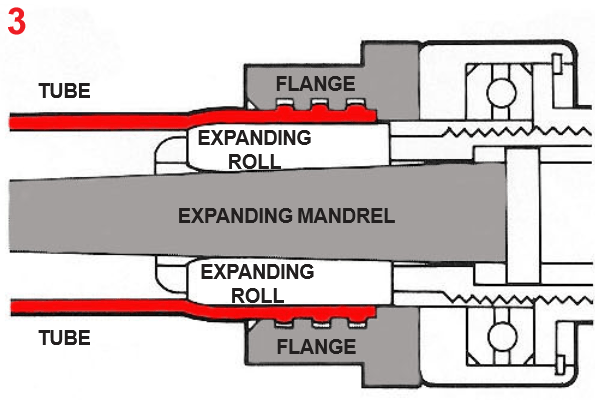

3) 50% Expansion

At this point the tube metal has begun to flow into the grooved serrations of the flange.

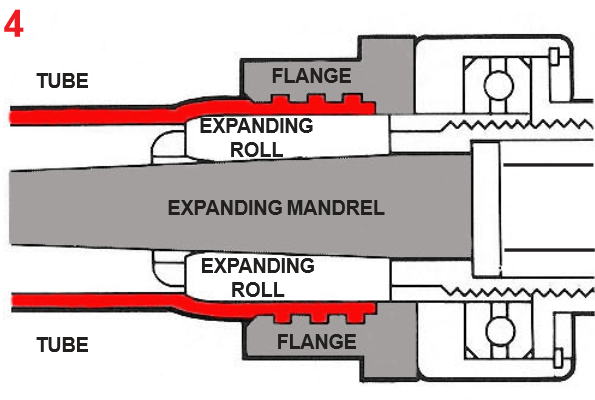

4) 100% Expansion

Grooved serrations are now completely filled and the tube metal has flowed to the point of least resistance beyond the flange resulting in a mechanically formed joint that will not leak, vibrate loose or pull apart.

For more information about metal finishing tools visit monaghantooling.com.

Monaghan Tooling Group is Elliott’s exclusive marketing and sales rep for our precision metal finishing tools.