How to calculate roll ID

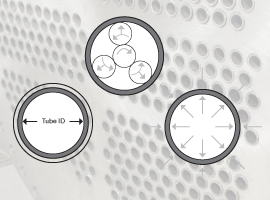

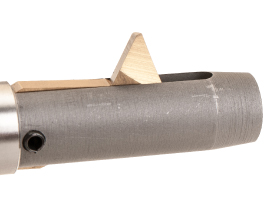

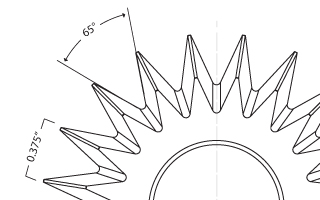

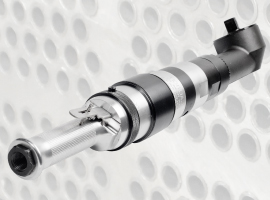

Erica Bray2021-05-18T09:57:38-05:00Tube Expanding is based on engineering principles, involving elasticity and plasticity, to compress the OD of the tube against a fixed container, such as rolling tubes into tube sheets, drums, ferrules or flanges. To assure a proper tube joint, the tube wall must be reduced by a predetermined percentage. The following chart can be used for determining the correct tube wall reduction.